BIO-DEGRADABLE

Environmental insurance for Single-Use Plastics

There is no one simple solution, no magic bullet to protecting our environment. However through the use of Reverte™ additive single-use plastics can safely biodegrade; reducing the impact on the environment.

FAQ

What is Reverte™?

Reverte™ is a Masterbatch additive developed and manufactured by Wells Plastics Limited (UK). It provides a safe and effective solution as a Biodegrade plastic after a product has had a useful life.

Reverte™ is a Masterbatch additive developed and manufactured by Wells Plastics Limited (UK). It provides a safe and effective solution as a Biodegrade plastic after a product has had a useful life.

For information about ReverteTM

from Wells Plastics Limited (UK):

How does it work?

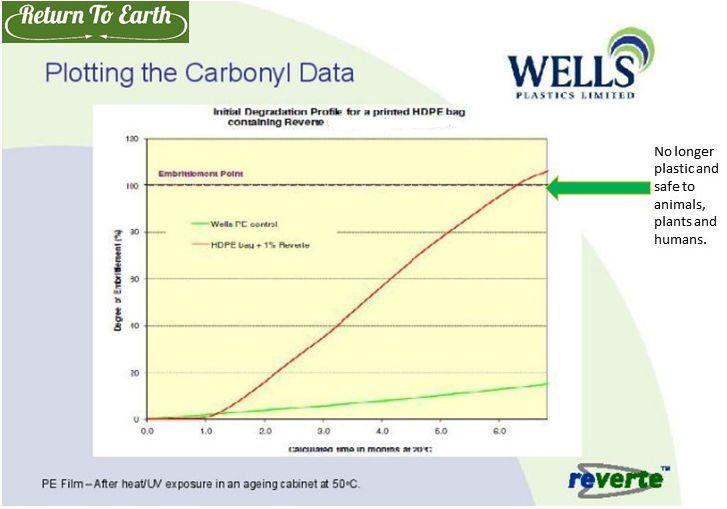

Once a Return To Earth® product is finished with, it can and should be recycled. However should it end up in the environment or waterways, it will safely Biodegrade. Once degradation has reached 100% embrittlement, it will be absorbed into the biomass without a trace. In waterways, a Reverte™ product breaks down into H2O and CO2. The oxidation process commences with exposure to natural sunlight and temperature above 1°C. It will continue even when deposited in landfill where temperature and oxygen exists.

Is it safe to use?

Reverte™ is 100% safe to use, with no harmful effects on human, animal, plant life, soil or waterways.

What about toxicity?

Reverte™ has been independently tested to the US CONEG and European Directive 94/62EC and found compliant to contain no heavy metals. It is also safe to come in contact with food passing USFDA, Canada (CFIA) and European (2002/72/EC) standards.

Can plastic products containing Reverte™ be recycled?

Biodegradable products made with the additive can safely enter the recycling streams unlike "Compostable" plastics which must be excluded from recycling. We should be making every endeavor to recycle.

What is guaranteed?

Reverte™ has been tested and passed the International standard, ASTM D 6954 - 18 for environmental compliance and safety for its Biodegradability.

Why the Return To Earth® guarantee?

All Return To Earth® products are checked and tested to ensure customers receive products of the highest integrity. This very important for all stakeholders.

Reverte™ has been tested and passed the International standard, ASTM D 6954 - 18 for environmental compliance and safety for its Biodegradability.

Why the Return To Earth® guarantee?

All Return To Earth® products are checked and tested to ensure customers receive products of the highest integrity. This very important for all stakeholders.

At RE-LIFE FOR PLASTICS we provide customers with a written guarantee to ensure they are comfortable that all products comply with the specified performance levels. We are not aware of any other company that provides such guarantees for the performance of environmental products.

Do Reverte™ products have a shelf life?

Unlike all other biodegradable additives; Reverte™ is a unique formula which provides a “Dwell Time” until it is exposed to natural sunlight where it will commence the process. If stored or exposed to artificial light (e.g. in a shop or warehouse), the products remain inactive.

Are there other Biodegradable additives?

Yes, there are other Biodegradable additives. However, Reverte™ has significant advantages over other technologies, including the complete absorption into the biomass.

Do Reverte™ products have a shelf life?

Unlike all other biodegradable additives; Reverte™ is a unique formula which provides a “Dwell Time” until it is exposed to natural sunlight where it will commence the process. If stored or exposed to artificial light (e.g. in a shop or warehouse), the products remain inactive.

Are there other Biodegradable additives?

Yes, there are other Biodegradable additives. However, Reverte™ has significant advantages over other technologies, including the complete absorption into the biomass.

Wells Plastics

Wells Plastics Limited are arguably the most experienced manufacturer of Biodegradable technology in the world today. Company staff are often invited to present papers at industry exhibitions and events, as well as holding specific seminars relating to aspects of the technology around the world. They are technical experts in the field of Biodegradable plastics and creators of Reverte™ products. Many of Wells Plastics' competitors do not manufacture their additives but use 3rd party companies to produce their Masterbatch materials. Therefore, they do not have the same controls or technical advantages of Reverte™ products.

For further information about Wells Plastics Limited visit the website:

The Biodegradable process

- Reverte™ is added to PP, PE or PET resins during the manufacturing process.

- Products are made, shipped, sold, stored and used. They can be recycled and should be wherever possible.

- Once exposed to the open environment, the products oxidization commences until the physical nature of the product has changed from plastic to carbonyl (i.e. non plastic).

- The material can now safely biodegrade in the environment, harmlessly absorbed into the biomass or water.

- This provides a safer insurance for waste plastic after use.

Why Reverte™?

Some of Reverte™ ’s distinctive advantages are as follows:

- A 1% addition rate of Reverte™ will allow the plastic bag to self-destruct after its useful life.

- Due to the control packages inherent in the patented technology, Reverte™ technology has superior heat sealing properties compared to other Biodegradable products. This has been tested and proven by independent laboratories. It ensures a Return To Earth® Garbage Bag / Bin Liner, checkout bag, produce bag, bottle or other products will perform to the highest possible standards.

- The Reverte™ dwell time is unique to its technology and provides a longer working life for products before being discarded.

- A Return To Earth® Reverte™ product can be recycled without affecting the immediate physical properties of a recycled PE film.

- Reverte™ has a two phase process; the first (oxidation) which is initiated through exposure to sunlight and heat, after the Dwell time. The secondary phase (biodegradation promoter) promotes the growth of microbial colonies. This speeds up and facilitates the ultimate biodegradation of the plastic following the initial oxo-breakdown in phase one.

- Wells Plastics provides ongoing technical support, testing and verification.

Find out more about Reverte™ . Email: info@relife4plastic.net

GENERAL ENQUIRIES - Head Office - Melbourne - Australia

ASIA - Office - Ho Chi Minh - Vietnam

Website by Netregistry